| T200 Cold-applied Outer Wrap Tape |

|

|

|

For corrosion protection of oil, gas, petrochemical, and waste water underground or overhead pipelines.

Product description:

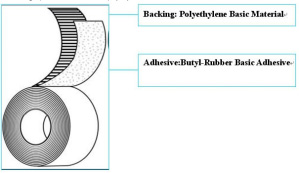

Construction: two-layer system

Adhesives: butyl rubber.

Backing: special blend of stabilized polyethylene.

The installation is carried out after the inner-layer tape by hand or with a wrapping machine. |

| Product features/benefits: |

|

|

Product features/benefits: |

|

•Resistant to UV

•Highly flexible, easy to apply at both low and high temperatures

•Excellent adhesion to inner-layer tape and itself.

•Easy to use and no special equipment required

•Compatible with common pipe coatings.

•Excellent resistance to cathodic disbonding.

•Cold applied. |

|

|

|

|

|

Max Service Temperature |

- 40 ℃ - 80℃ |

|

Application Temperature |

-10 ℃ - 60 ℃ |

|

Backing colour |

Black, yellow or others |

|

Outer wrap |

T238, T250, T265, T275, T290 |

|

Physical Properties |

Test Method |

T250 Typical Value |

|

English |

Metric |

|

Total thickness |

ASTM D 1000 |

25.0 mil |

0.50 mm |

|

Backing thickness |

ASTM D 1000 |

16.0 mil |

0.30 mm |

|

Adhesive thickness |

ASTM D 1000 |

9.0 mil |

0.20 mm |

|

Width |

- |

2’’- 32’’ |

50 -800 mm |

|

Length |

- |

100’ -800’ |

30 -240 m |

|

Water Vapor Transmission Rate (24h) |

ASTM F1249 |

0.1g/100sq mm/24h |

|

Tensile strength |

ASTM D 1000 |

29.1 lbs/in |

45 N/ cm |

|

Elongation |

ASTM D 1000 |

400 % |

|

Peel Adhesion to primed steel pipe |

ASTM D 1000 |

45 oz/in |

25 N/cm |

|

Cathodic Disbandment |

ASTM G8 |

0.25 in radius 6.4 mm |

|

Dielectric Strength |

ASTM D 149 |

40 Kv |

|

Volume Resistivity |

ASTM D 257 |

2.2x1012 ohm.cm |

|

Water Absorptivity |

ASTM D 570 |

0.067 % |

|

UV resistance |

- |

Excellent |

| All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. Products can be produced according to given specification. Please contact us for further information and confirmation. | |

|

|