| T100 Cold-applied Inner Wrap Tape |

|

|

|

For corrosion protection of oil, gas, petrochemical, and waste water underground or overhead pipelines.

Product description:

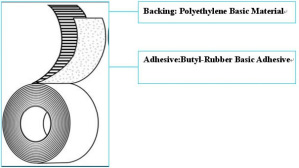

Construction:two-layer system

Adhesives: butyl rubber.

Backing: special blend of stabilized polyethylene.

The installation is carried out after the liquid adhesive and before the outer-layer tape by hand or with a wrapping machine. |

| Product features/benefits: |

|

|

Product features/benefits: |

|

• Highly flexible, easy to apply at both low and high temperatures

•Excellent adhesion to pipe and itself.

•Easy to use and no special equipment required

•Compatible with common pipe coatings.

•Excellent resistance to cathodic disbonding.

•Cold applied. |

|

|

|

|

|

Max Service Temperature |

- 40 ℃ - 80℃ |

|

Application Temperature |

-10 ℃ - 60 ℃ |

|

Backing colour |

Black, yellow or others |

|

Inner wrap |

T140, T150, T160, T170, T180 |

|

Physical Properties |

Test Method |

T150 Typical Value |

|

English |

Metric |

|

Total thickness |

ASTM D 1000 |

20.0 mil |

0.50 mm |

|

Backing thickness |

ASTM D 1000 |

12.0 mil |

0.30 mm |

|

Adhesive thickness |

ASTM D 1000 |

8.0 mil |

0.20 mm |

|

Width |

- |

2’’- 32’’ |

50 -800 mm |

|

Length |

- |

100’ -800’ |

30 -240 m |

|

Water Vapor Transmission Rate (24h) |

ASTM F1249 |

0.1g/100sq mm/24h |

|

Tensile strength |

ASTM D 1000 |

27 lbs/in |

45 N/ cm |

|

Elongation |

ASTM D 1000 |

400 % |

|

Peel Adhesion to primed steel pipe |

ASTM D 1000 |

228 oz/in |

25 N/cm |

|

Cathodic Disbandment |

ASTM G8 |

0.25 in radius 6.4 mm |

|

Dielectric Strength |

ASTM D 149 |

33 Kv |

|

Volume Resistivity |

ASTM D 257 |

2.2x1012 ohm.cm |

|

Water Absorptivity |

ASTM D 570 |

0.06 % |

| All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. Products can be produced according to given specification. Please contact us for further information and confirmation. | |

|

|