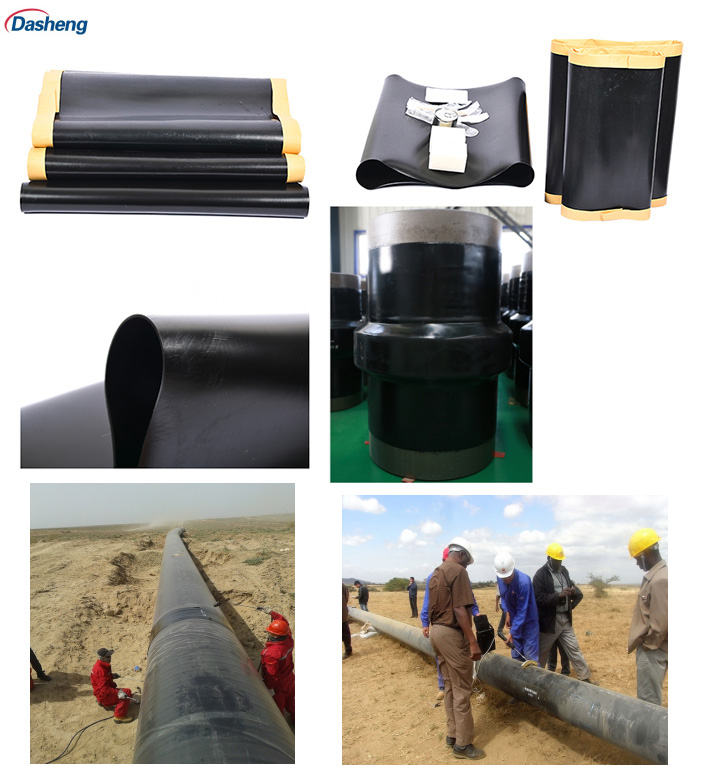

Product description:The TS60 is a heat shrinkable tubular sleeve designed for corrosion protection of buried and exposed steel pipelines. It consists of a crosslinked polyolefin backing, coated with a

protective heat sensitive adhesive which effectively bonds to steel

substrates and common pipeline coatings including polyethylene

and fusion bonded epoxy.

Construction: Three-layer system

First layer: Liquid epoxy, solvent-free two-component.

Second layer: High shear strength copolymer adhesive.

Third layer: Thick, fiberglass reinforced, radiation cross-linked polyethylene.

| Product features/benefits: |

|

•Dimpled backing provides a "Permanent Change Indicator"(PCI) for application of heat

Ensures correct application of heat & allows easy post-heat inspection.

Reliable inspectability at any time.

•No primer required

Saves installation time.

•Low preheat sensitivity & proven functionality

Allows easy application combined with high functional performance.

Saves installation time.

•Mechanically strong & resists abrasion, impact and penetration

Reliable and tough.

Remains user-friendly (even at low temperatures).

|

•Specially formulated sealants

Ensures a strong bond & a tight seal.

Provides high peel and shear values after installation.

•Sealing adhesive automatically flows and repairs minor mechanical damages

"Self-healing effect". Saves time

•No special equipment or skills required

Makes installation fast and easy.

Keeps installation costs low. |

|

Product selection guide

|

|

|

TS50 (mastic)

|

TS60

|

TS80

|

|

Max operating temperature

|

60℃

|

70℃

|

85℃

|

|

Compatible line coatings

|

PE, FBE, PP

|

PE, FBE, PP

|

PE, FBE, PP

|

|

Preheat temperature

|

60℃

|

70℃

|

85℃

|

|

Recommended pipe preparation

|

Clean, dry and free of grease

|

Clean, dry and free of grease

|

Clean, dry and free of grease

|

|

Performance

|

SY/T0413-2002 EN12008

|

SY/T0413-2002 EN12008

|

SY/T0413-2002 EN12008

|

|

Property

|

Test Method

|

Unit

|

Typical Value

|

|

TS50(mastic)

|

TS 60

|

|

Pipe Temperature (Max)

|

-

|

-

|

50ºC

|

60ºC

|

|

Tensile Strength

|

ASTM D638

|

psi

|

2,500

|

2,700

|

|

Ultimate Elongation

|

ASTM D638

|

%

|

500

|

500

|

|

Volume Resistivity

|

ASTM D257

|

Ω-cm

|

1x 1015

|

1x 1015

|

|

Dielectric Strength

|

ASTM D149

|

kV/mm

|

25

|

25

|

|

Water Absorption

|

ASTM D570

|

% (Wt)

|

0.05

|

0.05

|

|

Softening Point

|

ASTM E28

|

ºC

|

78

|

110

|

|

Peel Strength

|

DIN 30672

|

N/cm

|

60

|

60

|

|

Lap Shear Strength

|

DIN 30672

|

N/cm²

|

140

|

140

|

|

Impact Resistance

|

DIN 30672

|

J

|

> 15

|

> 15

|

|

Penetration Resistance

|

ASTM G17

|

-

|

Passes

|

Passes

|

|

Cathodic Disbandment

|

ASTM G42

|

mm-radius

|

-

|

10

|

|

Dielectric Breakdown

|

ASTM D149

|

kV

|

40

|

40

|

|

TS type products are available:

as ready-to-size tubular sleeves

Drawing sleeve width, pipe diameter

Take a 10% shrinkage during installation of sleeve width into account when calculating the minimum sleeve width.

|

|

Example:

|

TS60Φ273-1.2/0.8

|

|

TS

|

Product type

|

|

60

|

Operating temperature 60°C

|

|

Φ273

|

Outside pipe diameter in mm

|

|

1.2

|

Backing thickness in mm

|

|

0.8

|

Adhesive thickness in mm

|

|

* For pipe sizes exceeding DN200, the use of wrap-around WSS sleeves is recommended.

|

| All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. Products can be produced according to given specification. Please contact us for further information and confirmation. |