| WSS Heat Shrinkable Wrap-around Sleeve |

|

|

|

For corrosion protection of girth weld joint of buried steel pipeline

Especially for 3PE/3PP/ FBE factory coating pipeline

Product description:

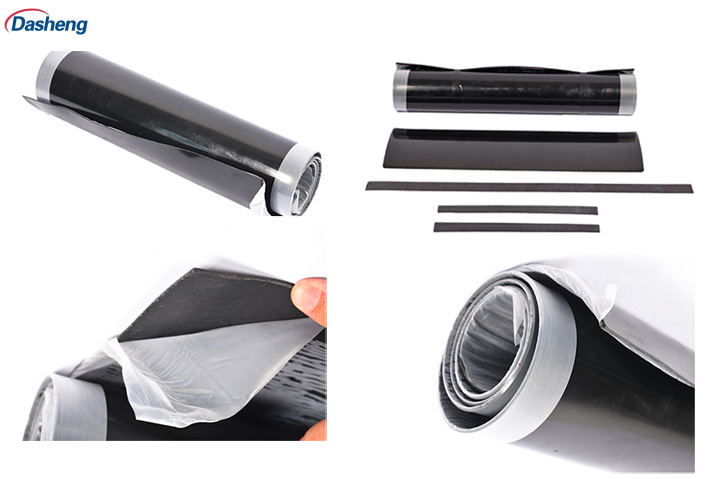

Construction: Three-layer system

• First layer: Liquid epoxy primer CP-1, solvent-free two-component

• Second layer: High shear strength hot-melt copolymer adhesive

• Third layer: Radiation cross-linked, high density polyethylene backing,

|

| Product features/benefits: |

|

• Excellent multifunctional adhesive allow for lower installation pre-heat temperature and super bonding to PE, PP and FBE, offer fully resistant to shear forces induced by soil and thermal movements.

• Superior cathodic disbondment and hot water immersion resistance offers the optimum barrier long term protection against corrosion.

• Saves time & cost by lower preheat temperature, wet epoxy primer application.

• Pattern backing provides a “heating temperature indicator” for application of heat, ensures correct applic-ation heating.

|

|

|

WSS 50(Mastic)

|

WSS 60

|

WSS 80

|

|

Standard reference

|

EN 12068 Class

C50

ISO21809-3

|

EN 12068 Class C50

NACE RP0303

ISO/DIS 21809-3

|

EN 12068 Class C HT UV

NACE RP0303

ISO/DIS 21809-3

|

|

Compatible line coatings

|

PE, FBE, Coal Tar,

AE

|

FBE, PE, PP

|

FBE, PE, PP

|

|

Soil stress restriction

|

None

|

None

|

None

|

|

Max operating temperature

|

60°C

|

60°C

|

80°C

|

|

Preheat temperature

|

50 - 60°C

|

50 - 70°C

|

60 - 80°C

|

|

Recommended pipe preparation

|

SA 2½ or ST 3.0

|

SA 2½ or ST 3.0

|

SA 2½

|

|

Property

|

Test method

|

Typical value

WWS50(mastic)

|

Typical value

(WSS60)

|

Typical value

(WSS80)

|

|

Epoxy primer

|

|

Solid content %

|

GB/T1728

|

99.5

|

3\99.5

|

99.5

|

|

Cathodic disbondment

(65℃, 48h) mm

|

Q/SY GJX0113-2007

|

8

|

8

|

8

|

|

Backing

|

|

Tensile strength Mpa

|

GB/T1040-92

|

21

|

24

|

24

|

|

Elongation %

|

GB/T1040-92

|

550

|

550

|

550

|

|

Density

|

ASTM D792

|

0.93

|

0.94

|

0.94

|

|

Adhesive

|

|

Softening point

|

GB/T4507-85

|

78

|

113

|

120

|

|

Shear strength Mpa

|

ASTM D1002-05

|

0.8

|

0.8

|

1.0

|

|

Sleeve

|

|

Peel to steel N/cm

|

GB/T2792-98

|

90

|

160

|

140

|

|

Peel to PE N/cm

|

GB/T2792-98

|

85

|

110

|

95

|

|

Cathodic disbondment

(70℃, 30d) mm

|

SY/T0413-2002 |

/

|

18

|

18

|

|

Water absorption

|

ASTMD570

|

0.001%

|

0.001%

|

0.001%

|

|

Ordering information:

|

|

WSS type products are available:

• as cut piece (pre-cut sleeve with separate closure patch)

• as a roll (closure patches to be ordered separately)

|

|

Example:

|

WSS60Φ559-1.5/1.0

|

|

WSS

|

Product type

|

|

60

|

Operating temperature 60°C

|

|

Φ559

|

Outside pipe diameter

|

|

1.5

|

Backing thickness

|

|

1.0

|

Adhesive thickness

|

|

|

Product thickness (mm)

|

|

Adhesive

|

Total thickness

(as supplied)

|

Total thickness

(recovered on pipe)

|

|

1.0

|

1.8

|

2.0

|

|

1.2

|

2.2

|

2.4

|

|

1.5

|

2.5

|

2.8

|

|

1.5

|

2.7

|

3.0

|

|

1.7

|

3.2

|

3.5

|

|

* Other sleeve thickness (1.4~3.5mm) are available

|

|

| All information contained in this technical data sheet is to be used as a guide and is subject to change without notice. Products can be produced according to given specification. Please contact us for further information and confirmation. |

|

|

|